2010-10-13

Blu Ray – structure, overall information

Overall information

Blu-ray Disc (BD) – competitive for the HD DVD format of the optical recording, created by the Blu Ray Disc Association BDA. This is the follower of the DVD format. Its capacity is larger than the DVD`s, which is possible due to the use of the blue laser. This new type of a carrier enables recording 25GB of data on a single-layer disc. There are also the double-layer discs that have 50GB of capacity. Moreover, there are even the four-layer discs that can store up to 100GB of data, and the eight-layer that can record up to 200GB of information. Pioneer company has patented the sixteen –layer disc that can store up to 400GB. In order to record on this disc, the blue laser is used (in the DVD recorders the red laser is used). The basic difference between these lasers is the wavelength- the red is 650 or 635 nanometers long, whereas the blue is only 405nm long.

The red lasers, which are used in the record on the DVDs, and the infrared lasers, that are used in the record on the CDs, produce light with the wavelength of respectively 640 and 790nm. In order to improve the recording, the light of 405nm wavelength, i.e. the violet light has been used. However, it is commonly thought that the blue light and the laser is used. The blue light is about 460nm long. The shorter wavelength enables decreasing of the size of pits and then it enables increasing of the density of the recording data on one unit of the carrier. The blu-ray disc has two layers: the first one is 1.1 mm thick, the other one- recordable- 0.1mm thick. A minimum length of a pit is 0.15um. A break between the tracks is 0.32µm, and the diameter of the laser’s spot is 0.48µm. BD-ROM requires a special, strong protective layer for the record track, which is placed 0.1mm below. There are three versions: BD-ROM (Read Only Memory), BD-R (Recordable), and BD-RE (Rewritable, up to 1000 records).

Technology

Gallium arsenide (GaAs), semiconductor that is essential to make the red laser, may be manufactured with the methods similar to these, which were implemented before for sillicon. Plates made form this material are excellent base, where with an extraordinary precision atoms that are an active part of the laser, which generates the light, are put, so called quantum cavity from several to teens atom layers thick. It is important that the base has no defects, which are called dislocations and the distances between the atoms of the base and in quantum cavities are the same. Fro red lasers these conditions are quite easy to meet. In case of the semiconductor blue laser the best base is another semiconductor, gallium nitride (GaN). The process of the production of mono-crystals is far more difficult than GaAs and it is similar to the process of the producition of synthetic diamonds, as both diamond and GaN are created in the extremely high pressure and temperature. Moreover, the high-pressure gaseous nitrogen’s use is required in case of GaN, what is technically very difficult. The process of the high-pressure crystallization of GaN seemed to be impossible and there were attempts to replace this base with the easily accessible sapphire bases since 60s XX century. The mismatch of the solid network of the sapphire and the gallium nitride deposited on it was the cause of the creation of significant number of structural defects (dislocation), which make the manufacturing of the effective instruments generating the blue laser impossible.

History

In 1992, a Japanese inventor, Shuji Nakamura constructed the first effective blue diode. Four years later, he made the first blue laser. Although the number of defects was very high (106-1010/cm2), Nakamura used a material deposited on the sapphire base. The presence of defects in the laser’s structure made a construction of the high power lasers significantly more difficult. At the beginning of 90s XX century in the Institute of High Pressures of Polish academy of Science (PAN) in Warsaw, under supervision of dr. Sylvester Porowski the technology of the obtaining gallium nitride crystals distinguished with the high structural quality was worked out. The number of defects was below 100/cm2, i.e. it was at least 10 000 times lower than in the best material deposited on sapphire so far. In 1999 Shuji Nakamura used the invented crystal to test the influence of defects on the properties of the lasers. The lasers constructed on the Polish crystal seemed to be much better than those constructed before, both in terms of life span and their productivity. The life span in case of 30mW power was increased ten times (from 300 to 3000 hours), and the productivity was increased more than twice. Further versatile development of technologies that started with the sapphire bases resulted with staritng of the production of the first mass product, which used the blue semiconductor lasers. After 10 years, the production of 60mW lasers was implemented in Japan. The power was enough to use them in dense recording of information in the currently presented Blu-ray discs BD-R and BD-RE. A technological successes of Nakamura, which created basics of the new field of light and electronic industries, were awarded Millennium Technology Prize in 2006, which is called the technological Nobel Prize.

Image and sound formats

On the Blu-ray discs image of films may be recorded in three compression formats. Traditional MPEG-2 offers the low level of the compression and ensures the top quality of the image. MPEG-4 AVC guarantees the comparable quality of the image with the twice higher compression rate. Microsoft promotes VC-1 format, which is known before as Windows Media 9. Sound may be encoded with one of obligatory codecs: DTS Dolby Digital & LPCMD. The optional codecs are: Dolby Digital Plus, DTS-HD High Resolution Audio, Dolby TrueHD, and DTS-HD Master Audio. Audio and video may also be recorded as ordinary files, in any format.

Drives

The companies, which promote this format of recording, supply the BD players and the computer drives. The format is used in Sony PlayStation 3, which also has a function of the player. This format won the battle against HD DVD for the follower of DVD format.

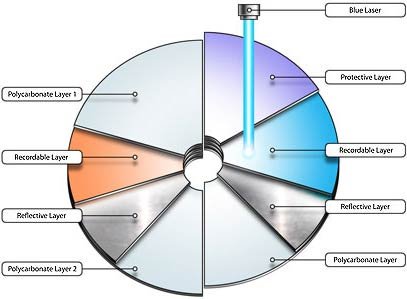

Illustrative structure of Blu Ray

In the picture below a scheme of the BD disc structure is presented.

- Upper layer of polish- used for any descriptions and labels on the disc.

- Polycarbonate layer - 1.1 mm thick disc, on which particular layers are put.

- Recordable layer (number one) - on this layer your data are recorded.

- Translucent separating layer- it separates two recordable layers. It is presented only in the double-layer discs.

- Recordable layer (number two) - the other recordable layer (only in the double-layer discs).

- Protective layer - much thinner layer that protects the layer, on which data have been recorded.

- Hardening protective layer - a special layer that protects the carrier against damages.

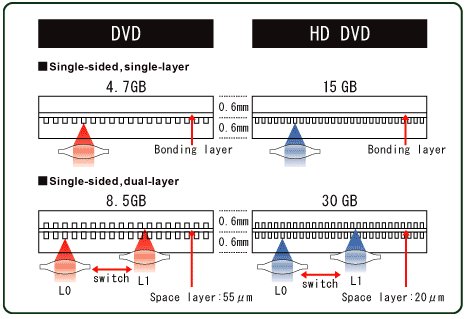

We should mention here that the thickness of the disc is 1.2mm. However, the thickness of the polycarbonate disc is 1.1mm. In other words, the rest is only 0.1mm thick. That is why, the damaged Blu Ray discs are so difficult to repair and their regeneration requires special processes and materials. To present better the issue of the thin protective layer in the regeneration context, here is a graphical presentation of the Blu Ray structure in comparison with the other formats.

(Source: Wikipedia.pl; cdrinfo.pl;)

Also see:

DVD - structure, overall information

CD - structure, overall information